How to Build a Floating Bed Frame

A floating bed frame provides a modern, minimalist aesthetic, creating the illusion that the bed is suspended in air. This guide outlines the steps involved in constructing a sturdy and visually appealing floating bed frame. While woodworking experience is beneficial, a novice with the proper tools and careful execution can achieve satisfying results.

Planning and Material Selection

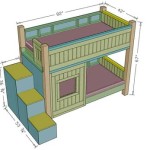

Careful planning is paramount to a successful build. Begin by determining the desired dimensions of the bed frame. Standard mattress sizes provide a useful starting point. Consider the height of the platform; a typical height ranges from 12 to 18 inches, but this can be adjusted to personal preference. Sketching a detailed diagram with accurate measurements is highly recommended. This diagram should include the dimensions of all supporting components, including the outer frame, inner supports, and central support beam.

Material selection impacts both the structural integrity and the final appearance of the bed frame. High-quality lumber, such as kiln-dried pine or hardwood, is recommended for its strength and durability. The thickness of the lumber should be chosen based on the size of the bed and the expected weight. For a queen or king-size bed, lumber with a thickness of at least 2 inches is recommended. Additionally, select appropriate screws and fasteners designed for wood construction, ensuring they are long enough to securely join the pieces.

Constructing the Frame

The construction process starts with building the outer frame. Cut the lumber according to the dimensions specified in the plan. These pieces will form the perimeter of the bed and provide the primary visual element of the “floating” effect. Assemble the outer frame using wood glue and screws, ensuring square corners and a level surface. Pocket hole joinery can provide a clean, professional finish, hiding screw heads for a more aesthetically pleasing result. Clamps are essential during the assembly process to hold the pieces firmly in place while the glue dries.

Next, build the inner support structure. This typically consists of a series of crossbeams running perpendicular to the outer frame. These crossbeams should be spaced evenly to provide adequate support for the mattress and occupants. Attach these crossbeams to the outer frame using screws and glue, ensuring a secure connection. A central support beam, running down the middle of the frame, is crucial for larger beds to prevent sagging. This beam should be securely attached to both the outer frame and the inner crossbeams.

Finally, attach the platform to the inner support structure. This platform can be constructed from plywood or slats. Plywood provides a solid surface, while slats offer better ventilation for the mattress. Ensure the platform is securely attached to the support structure using screws. The top surface of the platform should be flush with the top edges of the outer frame.

Finishing and Installation

Once the frame is assembled, sand all surfaces smooth to remove any splinters or rough edges. Apply a finish of your choice to protect the wood and enhance its appearance. Options include paint, stain, or clear sealant. Allow the finish to dry completely before placing the mattress on the frame.

The "floating" effect is achieved by minimizing visible supports. The bed can be positioned directly on the floor, creating a low-profile look. Alternatively, recessed legs can be installed in the corners of the frame. These legs should be short enough to be largely concealed, maintaining the illusion of a floating platform. If using recessed legs, ensure they are level and provide stable support for the bed.

Customization and Considerations

The basic design presented here can be customized to suit individual needs and preferences. Consider adding features such as under-bed lighting, built-in storage drawers, or a headboard. For added stability, particularly with larger beds, consider using metal brackets to reinforce the connections between the frame components.

Always prioritize safety throughout the construction process. Wear appropriate safety gear, such as eye protection and a dust mask. Double-check all measurements and connections to ensure a sturdy and stable frame. If uncertain about any aspect of the construction process, consult with an experienced woodworker or contractor.

How To Build A Diy Floating Bed For Queen Size Mattress Thediyplan

King Size Floating Bed Frame Easily Build Your Own Plans Diy

King Size Floating Bed Frame Easily Build Your Own

Diy Floating Bed Frames How To Design Plan And Build Them From Scratch

Floating Bed Frame Plans Myoutdoorplans

Full Size Floating Bed Plans Howtospecialist How To Build Step By Diy

Floating Queen Size Platform Bed Plans Howtospecialist How To Build Step By Diy Frame

Floating Bed Frame Digital Plans

How To Easily Build A Diy Floating Bed With Led Lights

Floating Bed Frame Plans Diy Platform